Advantages of gate valve:

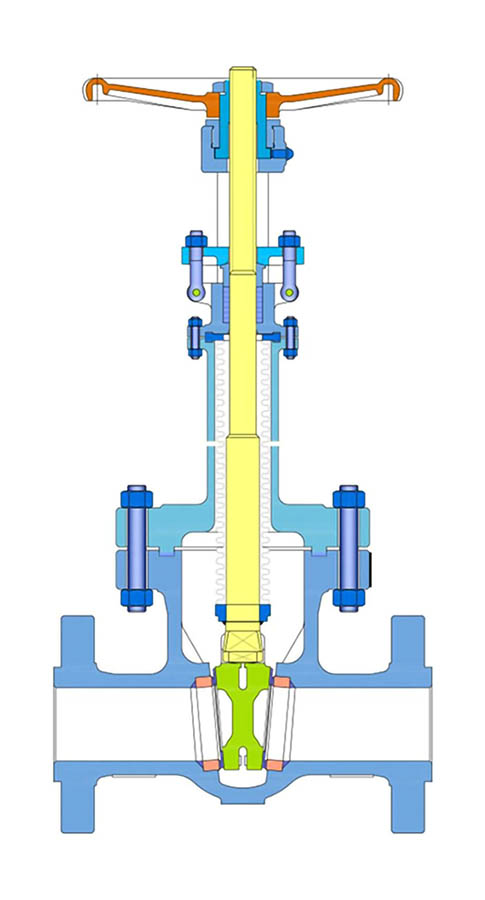

- Low fluid resistance

- The torque required for opening and closing is small

- It can be used on the loop network pipeline where the medium flows in two directions, that is, the flow direction of the medium is not limited.

- when it is fully open, the erosion of the sealing surface by the working medium is smaller than that of the stop valve

- The shape structure is relatively simple and the manufacturing process is good

- The structure length is relatively short

Disadvantages of gate valve:

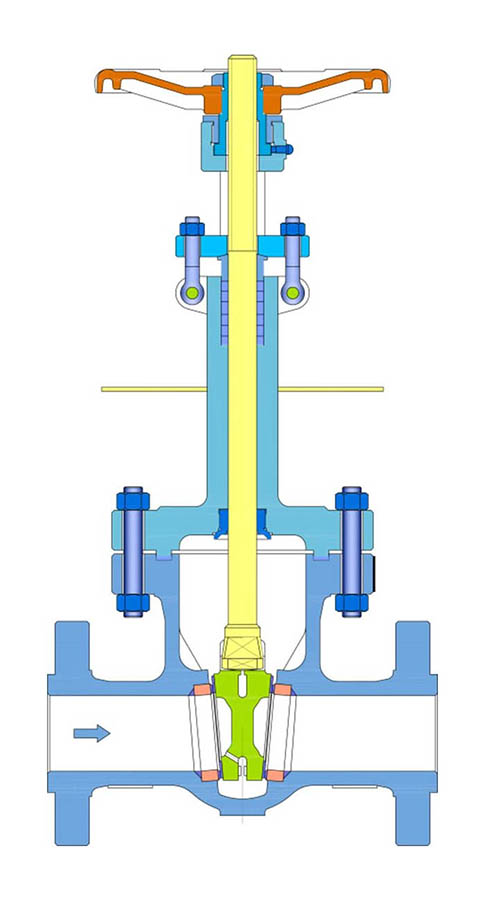

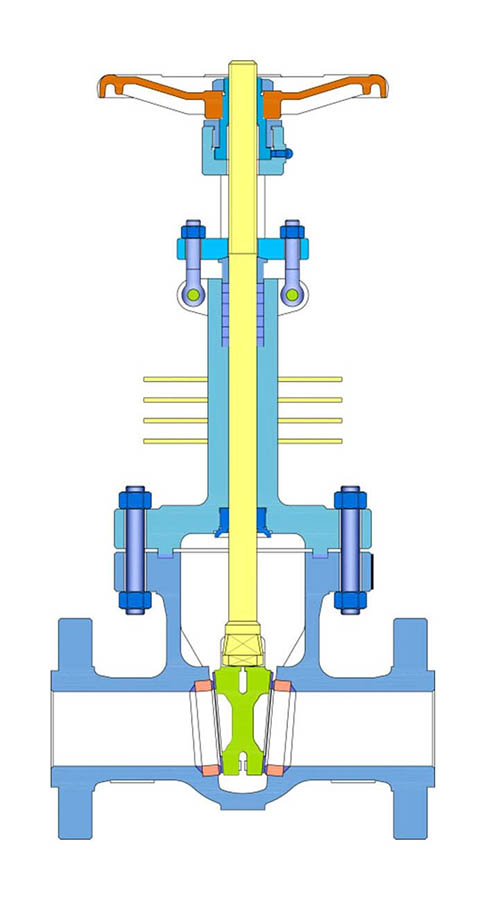

- The overall dimension and opening height are relatively large, and the installation space is also large

- In the process of opening and closing, there is relative friction between the sealing surfaces, which causes great wear and tear, and it is easy to cause Scratch even at high temperature

- Generally, the gate valve has two sealing surfaces, which increases some difficulties in processing, grinding and maintenance

- Long opening and closing time