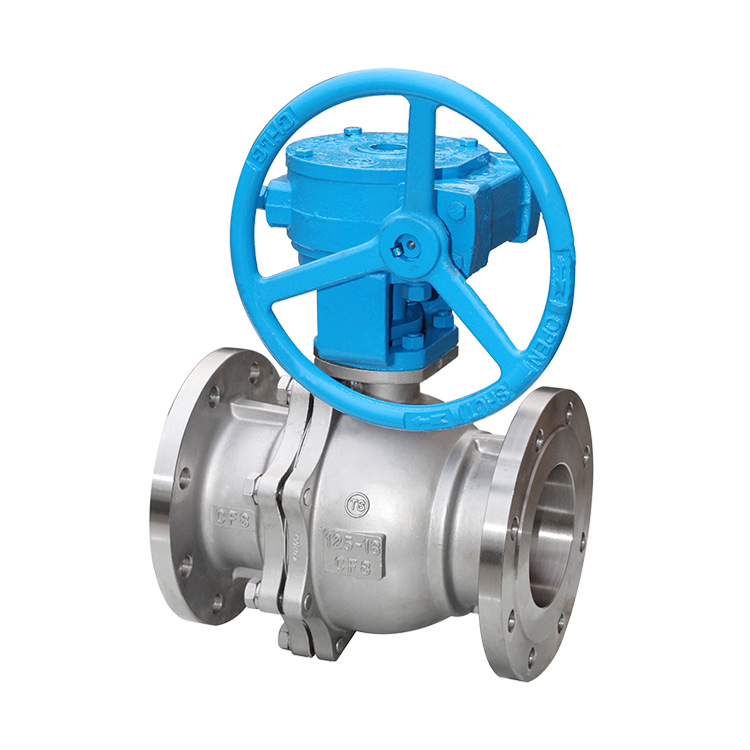

Ball valve

- Body material: Carbon steel, Stainless steel, Alloy steel,ect

- Size range(s): 1/2″~12″

- End: RF, RTJ, BW

- Pressure rating: Class150~Class2500

operation: Lever, gearbox, Electric-actuator, Pneumatic- actuator, etc.

- Body material: Carbon steel, Stainless steel, Alloy steel,ect

- Size range(s): 2″~60″

- End: RF, RTJ, BW

- Pressure rating: Class150~Class2500

operation: Lever, gearbox, Electric-actuator, Pneumatic- actuator, etc.

- Body material: Carbon steel, Stainless steel, Alloy steel,ect

- Size range(s): 2″~48″

- End: RF, RTJ, BW

- Pressure rating: Class150~Class1500

-

operation: gearbox, Electric-actuator, Pneumatic- actuator, etc.

- Body material: Carbon steel, Stainless steel, Alloy steel,ect

- Size range(s): 2″~48″

- End: RF, RTJ, BW

- Pressure rating: Class150~Class2500

operation: Lever, gearbox, Electric-actuator, Pneumatic- actuator, etc.

- Body material: Carbon steel, Stainless steel, Alloy steel,ect

- Size range(s): 1/2″~8″

- End: RF, RTJ, BW, NPT

- Pressure rating: Class150~Class2500

operation: Lever, gearbox, , etc.

- Body material: Stainless steel, Alloy steel,ect

- Size range(s): 1/2″~24″

- End: RF, RTJ, BW, NPT

- Pressure rating: Class150~Class1500

operation: Lever, gearbox, Electric-actuator, Pneumatic- actuator, etc.