Introduction To Butterfly Valve

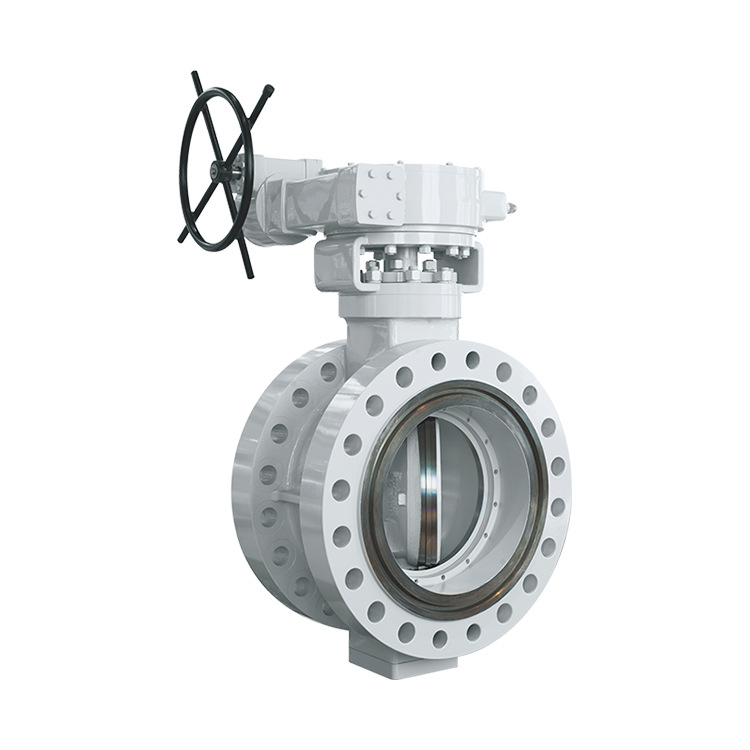

The opening and closing part of the butterfly valve is a disc-shaped butterfly plate, which rotates around its own axis in the valve body, so as to achieve the opening and closing or adjustment of the valve is called the butterfly valve. The butterfly valve is usually less than 90 degrees from full opening to full closing. The butterfly valve and the butterfly rod itself have no self-locking force. In order to position the butterfly plate, a worm gear reducer should be installed on the valve rod. Using worm gear reducer can not only make the butterfly plate have self-locking ability, stop the butterfly plate at any position, but also improve the operating performance of the valve.

The opening and closing part of the butterfly valve is a disc-shaped butterfly plate, which rotates around its own axis in the valve body, so as to achieve the opening and closing or adjustment of the valve is called the butterfly valve. The butterfly valve is usually less than 90 degrees from full opening to full closing. The butterfly valve and the butterfly rod itself have no self-locking force. In order to position the butterfly plate, a worm gear reducer should be installed on the valve rod. Using worm gear reducer can not only make the butterfly plate have self-locking ability, stop the butterfly plate at any position, but also improve the operating performance of the valve.