Introduction To Check Valve

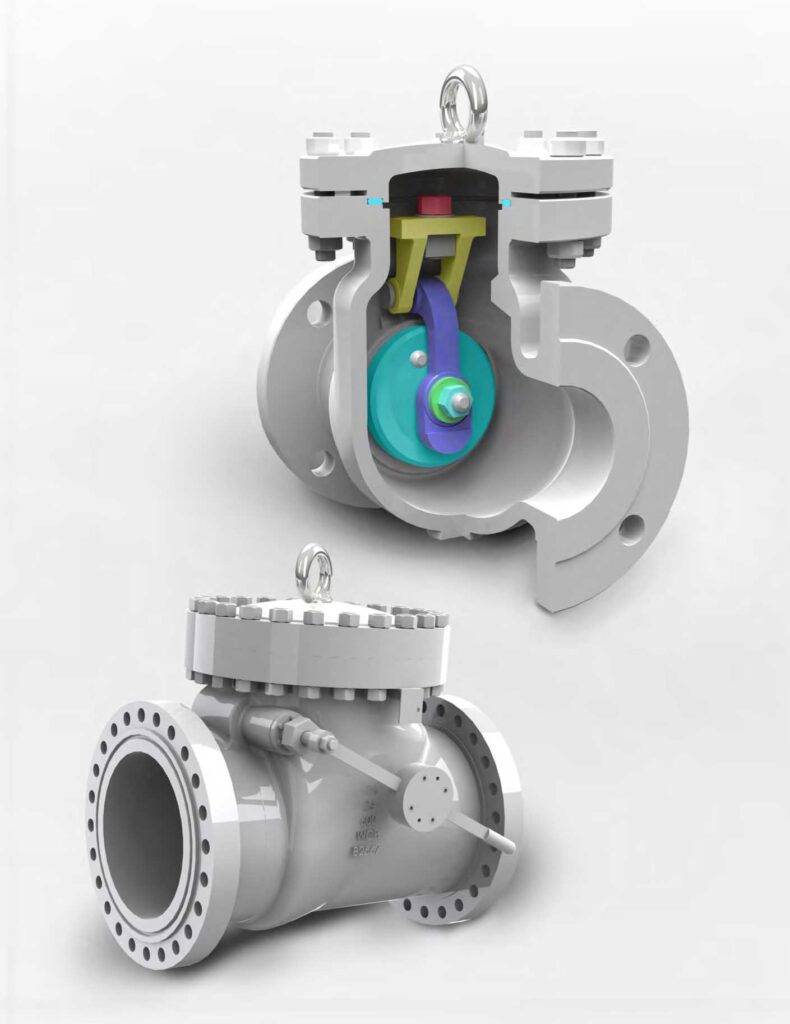

Check valve is also called counter flow valve, check valve, back pressure valve, one-way valve. This kind of valve automatically opens and closes by the force generated by the flow of the medium itself in the pipeline.

It belongs to an automatic valve. The main function of the check valve in the pipeline system is to prevent the backflow of the medium, the reverse rotation of the pump and its driving motor, and the discharge of the medium in the container

How to select the check valve

- In order to prevent the reverse flow of the medium, check valves shall be installed on equipment, devices, and pipelines;

- The check valve is generally applicable to the clean medium, and is not suitable for the medium containing solid particles and high viscosity;

- Straight through lifting check valve can be installed on both horizontal and vertical pipes;

- For the inlet pipeline of the water pump, the check valve should be selected

- The lifting type has better sealing performance and greater fluid resistance than the swing type,

- The installation position of the swing check valve is not limited. It can be installed on horizontal, vertical, or inclined pipelines. If installed on vertical pipelines, the medium flow direction should be from bottom to top;

- The check valve is applicable to low pressure and large diameter, and its installation is limited;

- The installation position of the wafer check valve is not limited. It can be installed on a horizontal pipeline, vertical or inclined pipeline;