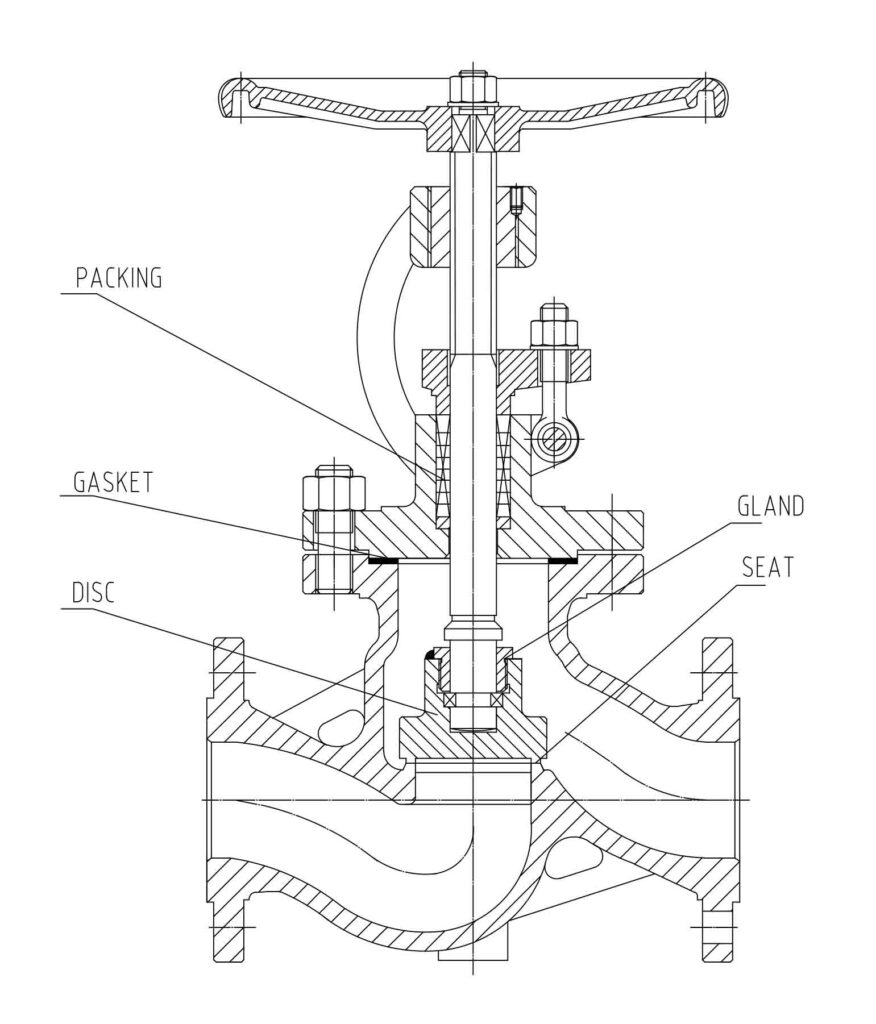

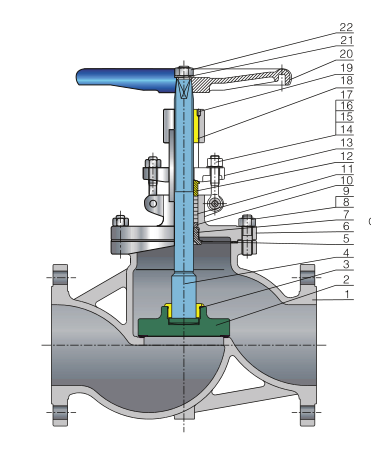

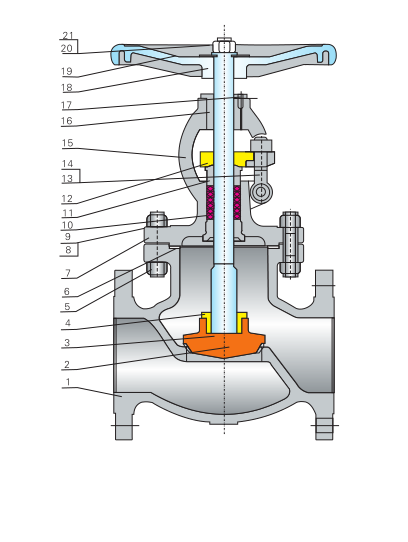

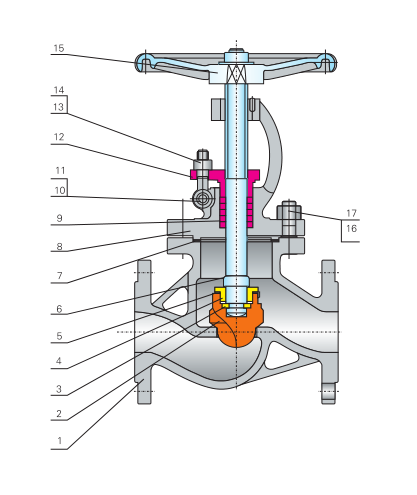

Introduction To Globe (Stop) Valve

the globe (stop) valve is a plug-shaped disc which opening and closing part, the sealing surface is flat or conical, and the disc moves in a straight line along the center line of the fluid. The movement form of the valve rod includes lifting rod type (the valve rod is lifted and the handwheel is not lifted), and lifting rotating rod type (the handwheel rotates and lifts with the valve rod, and the nut is set on the valve body). Ordinary globe (stop) valve is only applicable to full open and full close, and regulation and throttling are not allowed. There is a special regulating throttle globe(stop) valve.

The globe(stop) valve is a forced sealing valve, so when the valve is closed, pressure must be applied to the valve disc to force the sealing surface not to leak. When the medium enters valve from below the valve disc, the resistance to be overcome by the operating force is the friction between the valve rod and the packing and the thrust generated by the pressure of the medium. The force to close the valve is greater than the force to open the valve, so the diameter of the valve rod should be larger, otherwise the valve rod bending fault will occur